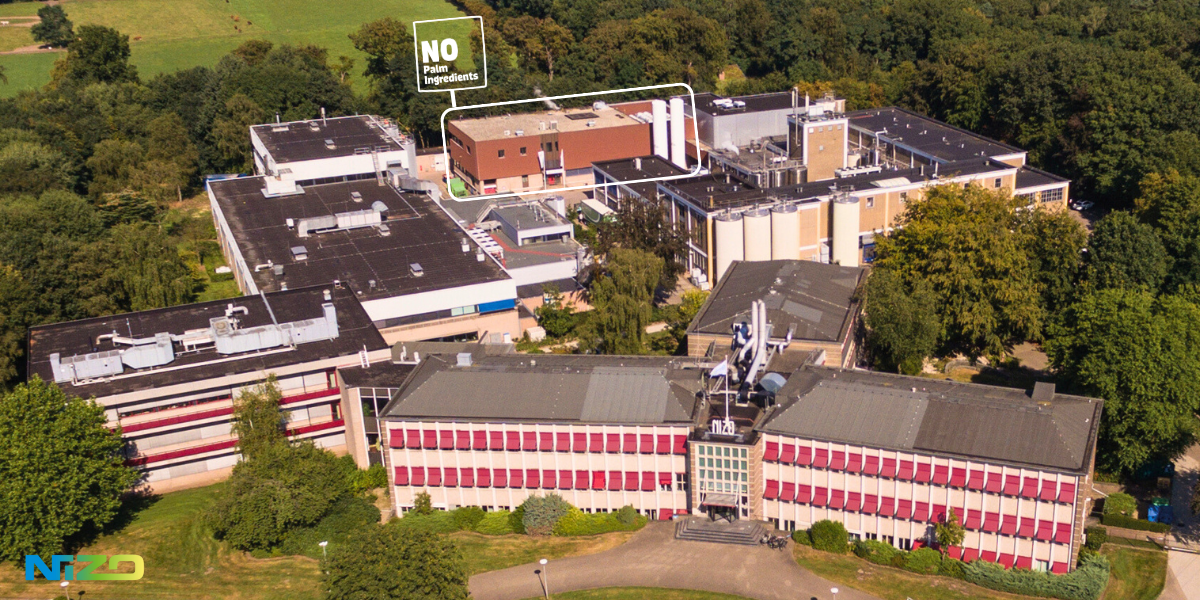

NoPalm Ingredients and NIZO Sign Agreement for Demonstration Factory at the Food Innovation Campus in Ede

We’re excited to share that together with our partner NIZO Food Research, we’re setting up our very first Demonstration Factory at the Food Innovation Campus in Ede.

For the first time, we’ll be running our full process for producing sustainable palm and other tropical oil alternatives, such as coconut oil and shea butter alternatives, under one roof. This marks our transition from pilot scale to commercial production, a big step toward making circular yeast oil a reliable and large-scale solution for the food and cosmetics industries.

Food Innovation Campus in Ede

From Lab to Factory

“The step towards our first factory is a concrete milestone in our ambition to become a leader in yeast oil production,” says Lars Langhout, our CEO and Co-founder of NoPalm Ingredients.

“From a shaking flask and a microscope in the lab, we are now building our own factory: dreams are becoming reality. As pioneers, we are showing the industry that yeast oils no longer only exist in the lab, but can also be produced at large scale, and that we are a reliable partner for sustainable oil alternatives.”

What This Factory Means

Until now, different steps of our process have happened at different sites. With the new demo factory, everything comes together in one location. This makes production faster, more efficient, and easier to scale.

Starting capacity: several hundred tons per year, growing to more than 1,200 tons.

For customers: it enables customers to replace conventional oils and make their products more sustainable, while the site also provides space for testing new raw materials and process improvements.

For raw material suppliers and buyers: a guarantee of reliable deliveries, supported by long-term contracts and optimized logistics.

“For our customers, this factory demonstrates that we are ready to deliver at an industrial scale,” says Julie Cortal, CCO at NoPalm Ingredients.

“We have proven that our technology works, and by taking the entire process into our own hands, we maintain maximum control over every step: from raw material to end product. This guarantees consistent quality, high standards, and security of supply, and with that, a solid foundation for long-term partnerships with customers who want to become more sustainable and grow.”

Why Ede?

Since 2023, NIZO has been developing the Food Innovation Campus, where leading players in the protein and food transition come together to scale innovations. This activity strengthens the region as an international center for biotechnology and the food transition.

“The arrival of NoPalm Ingredients fits perfectly with our ambition to further develop the NIZO Food Innovation Campus into the place for sustainable food innovation. They strengthen the fermentation cluster in the region and apply fermentation to fats, an often overlooked but essential part of both the protein and food transition.””

By using NIZO’s infrastructure, we can start building more quickly and cost-effectively. First industrial production is planned for the second half of 2026, with further growth in 2027 and 2028. The new site will create around 25 jobs, in addition to the 25 colleagues already working at our Wageningen HQ.

Looking Ahead

“With this factory, we are taking our technology to ‘technology readiness level’ 7 and 8, and bringing the full process under our own control at industrial scale,” says Jeroen Blansjaar, COO at NoPalm Ingredients.

“This is the crucial step that paves the way for our first commercial factory, which we aim to build together with a side stream partner at their site. This significantly reduces risks, both for ourselves and for our partners.”

This project has been made possible with the support of Oost NL, the Province of Gelderland, and the Municipality of Ede, partners who share our mission to expand circular food production in the region.

The permit procedure is moving forward as planned, and we can’t wait to open the doors of our first demonstration factory.